ss158284

Dec 12, 2016

Writing Feedback / WRITING TASK 1 Process making of bricks for building industry [2]

Hi, this is my first essay :)

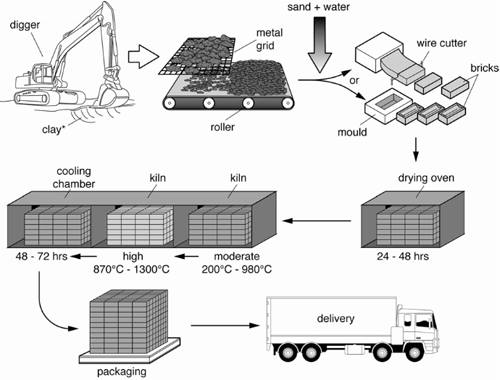

The diagram presents a man-made linear process started by using clay to dig up metal grid and ended with the delivery of bricks for the building industry. Although the third stage of process is distinguished by 2 types of cutting process, the whole process is equal, it can be clearly seen that the method of production has seven stages, beginning with the digging up of clay and culminating in delivery.

Firstly, the loam used to make the blocks is dug up from the ground by a big digger. Before placing the clay onto a metal grid there is prepared a roll equipment to roll the loam used to break up the loam into smaller pieces. After that, sand and water are added to the clay, and those mix components are moulded into blocks, at this stage it was distinguished by 2 ways of cutting (using mould or using a wire cutter). Next, these bricks are placed to an oven to be dried for 24 - 48 hours.

In the following stages, the bricks go through two kilns rooms and a cooling chamber. Those kilns heat up the blocks in different temperature (in first kiln at a moderate temperature and then a high temperature ranging from 200c to 1300c in the second kiln), then followed by a cooling process in a chamber for 48 - 72 hours days. Finally, the bricks are packed and shipped to their destinations.

Hi, this is my first essay :)

The diagram presents a man-made linear process started by using clay to dig up metal grid and ended with the delivery of bricks for the building industry. Although the third stage of process is distinguished by 2 types of cutting process, the whole process is equal, it can be clearly seen that the method of production has seven stages, beginning with the digging up of clay and culminating in delivery.

Firstly, the loam used to make the blocks is dug up from the ground by a big digger. Before placing the clay onto a metal grid there is prepared a roll equipment to roll the loam used to break up the loam into smaller pieces. After that, sand and water are added to the clay, and those mix components are moulded into blocks, at this stage it was distinguished by 2 ways of cutting (using mould or using a wire cutter). Next, these bricks are placed to an oven to be dried for 24 - 48 hours.

In the following stages, the bricks go through two kilns rooms and a cooling chamber. Those kilns heat up the blocks in different temperature (in first kiln at a moderate temperature and then a high temperature ranging from 200c to 1300c in the second kiln), then followed by a cooling process in a chamber for 48 - 72 hours days. Finally, the bricks are packed and shipped to their destinations.

tes.jpg