phuong10d2tb

Jun 8, 2020

Writing Feedback / IELTS WRITING TASK 1: DIAGRAM: the process of manufacturing bricks for the building industry [2]

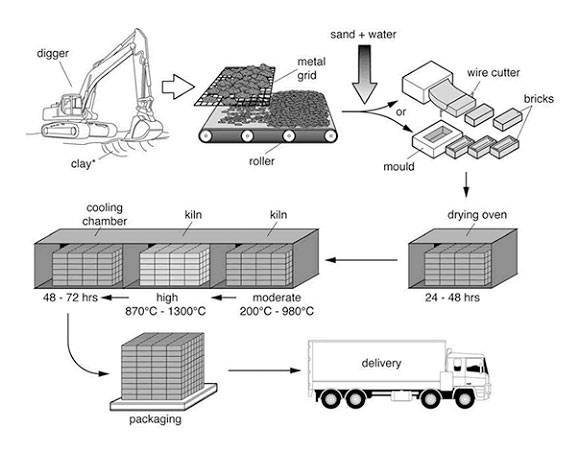

The diagram illustrates the process that is used to manufacture bricks for the building industry. Summarise the information by selecting and reporting the main features and make comparisons where relevant.

The picture explains how to make bricks for the buiding industry.

It is clear from the diagram that the process consists of seven stages, starting with collecting raw material and ending up with delivering products to customers.

Firstly, clay is digged by a large digger before being sorted out by a mental grid and falling onto a machine with rollers. Next, the clay is mixed with water and sand, and this mixture is poured into either a mould or a wire cutter to form bricks.

Bricks, after being dried in a dried oven for 24 to 48 hours, are then put into a kiln with a moderate temperature of 200 to 980 degree celcisus. Following this, temperature in the kiln is risen to a high level, ranging from 870 to 1300 degree celsius. Finally, bricks are cooled down in a cooling chamber for 48 to 72 hours before being packaged and delivered to customers.

How the bricks are produced

The diagram illustrates the process that is used to manufacture bricks for the building industry. Summarise the information by selecting and reporting the main features and make comparisons where relevant.

The picture explains how to make bricks for the buiding industry.

It is clear from the diagram that the process consists of seven stages, starting with collecting raw material and ending up with delivering products to customers.

Firstly, clay is digged by a large digger before being sorted out by a mental grid and falling onto a machine with rollers. Next, the clay is mixed with water and sand, and this mixture is poured into either a mould or a wire cutter to form bricks.

Bricks, after being dried in a dried oven for 24 to 48 hours, are then put into a kiln with a moderate temperature of 200 to 980 degree celcisus. Following this, temperature in the kiln is risen to a high level, ranging from 870 to 1300 degree celsius. Finally, bricks are cooled down in a cooling chamber for 48 to 72 hours before being packaged and delivered to customers.

xieltsprocessbrick.jpg