how a lead pencil is made

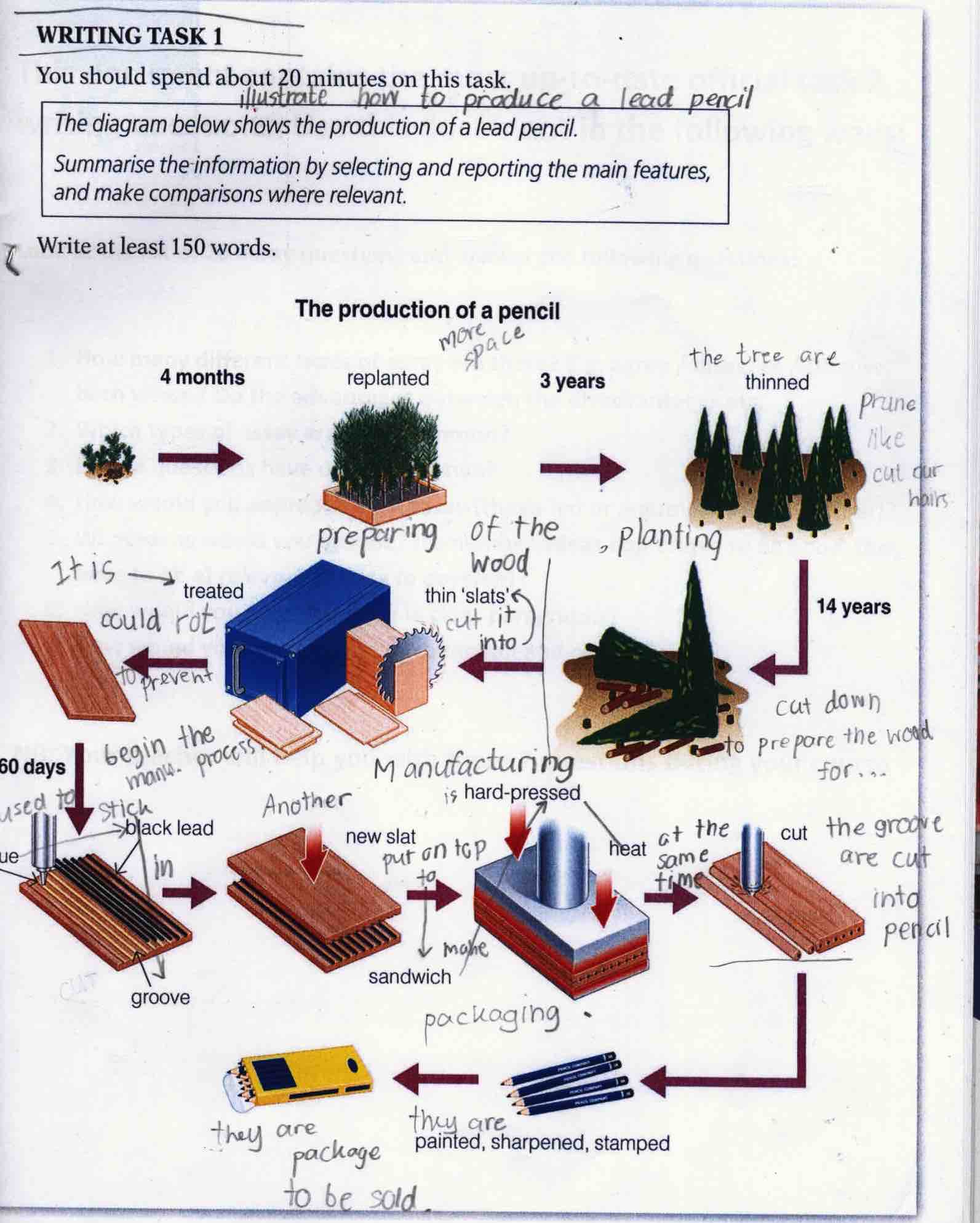

The diagram below illustrates how to produce a lead pencil. Overall, there are three stages in the process, starting with planting the trees, manufacturing, and then ending in packaging.

Firstly, the seeds are sowed in order to start growing the trees. Then, after four months, the seedlings are replanted so as to get more space. Three years after that, the trees are thinned to increase the growth potential. Following this, after fourteen years, the trees are chopped down to prepare the woods for the manufacturing process.

When the woods have been cut into thin slats, they are subsequently treated to prevent them from being rotted. Next, sixty years later, the glue is used to stick the black leads in the groove. It is only after this stage that another slat is put on top to make a sandwich after which the sandwich is hard-pressed whilst heated at the same time. The grooves are then cut into pencils. Finally, the pencils are painted, sharpened and stamped. This is the last process before they get packaged and ready to be sold.

Scan.jpg