Bricks for build purpose - manufacturing process

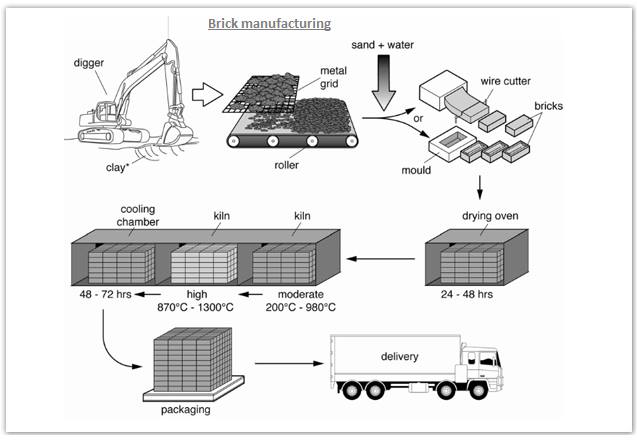

The diagram describes how bricks are created by manufacture industries. This process consists of six steps, which the main material such as clay were taken from nature and all process help by machines. As result the brick is ready to deliver and can be apply for building structure.

In the beginning clay was collected by digger and sent in trough metal grid in purpose to separated undesirable materials and fall direct to roller. Secondly clean clay being mixture by added sand and water to produce wet dough of clay. Next steps dough size is measured by using wire cutter, after it to give the brick's shade, dough was pressed inside mold.

Move to further steps the wet bricks are placed into drying oven for maximum three days. After half dried it move to kiln room for set the brick. There are including three stages, the first one with moderate temperature, second the highest degree between 870o - 1300o C and last but not least bricks are placed at cooling chamber for minimum a couple day or 48 - 72 hours. When the brick set they move into packaging and ready deliver to destination.

wt._1_kamis.jpg