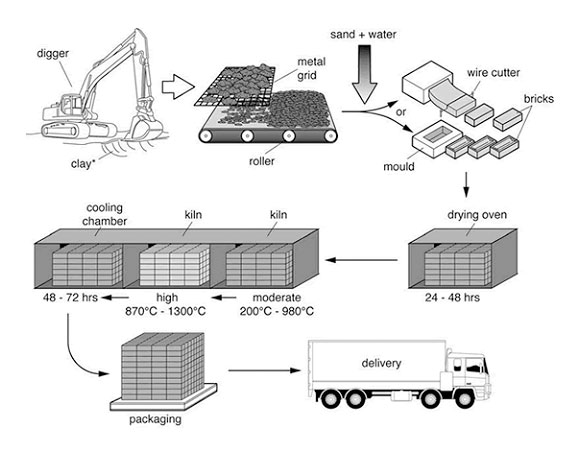

The picture shows how clay can process to become bricks and then they can sell to society.

Generally, bricks have many processes before they are selt to people.

Firstly, the company take clay from earth, it uses digger to make easier and faster to get clay. After that, clay must be enter to metal grid to roller then it mixes with sand and water before it happens product.

Secondly, this step is a long process. Brick must be enter in drying oven about two days, after that brick mast be enter again into cooling chamber about three days with temperature from 870˚C to 1300˚C. After this long process, bricks can be packaging and company can delivery to society.

Overall, it can be concluded that making bricks is very difficult. It needs long time.

Generally, bricks have many processes before they are selt to people.

Firstly, the company take clay from earth, it uses digger to make easier and faster to get clay. After that, clay must be enter to metal grid to roller then it mixes with sand and water before it happens product.

Secondly, this step is a long process. Brick must be enter in drying oven about two days, after that brick mast be enter again into cooling chamber about three days with temperature from 870˚C to 1300˚C. After this long process, bricks can be packaging and company can delivery to society.

Overall, it can be concluded that making bricks is very difficult. It needs long time.

ieltsprocessbricks.jpg