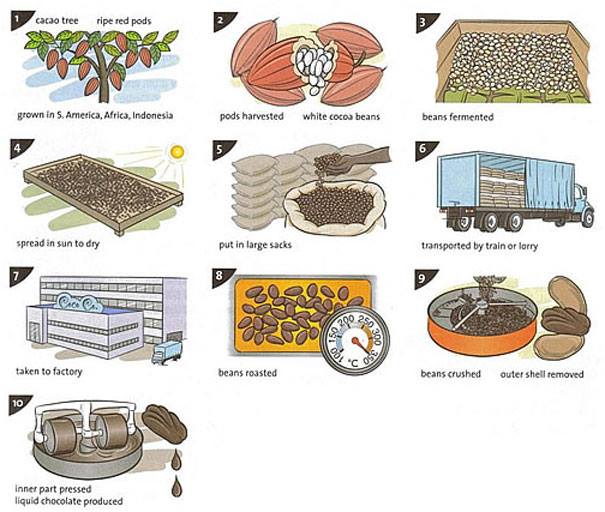

The diagram depicts the process of making chocolate. It is noticeable that there are several stages in the process, started in growing of ripe red pods on the cacao trees until concluding in the production of chocolate produced at factory.

To begin, the raw material of cacao comes from cacao trees, which is grown in the South American, African and some territorial in Indonesia. After the pods are ripe and red, they can be harvested and the white cocoa is separated in order to be fermented. Following a day of fermentation, they are laid out on the board which spread over to get a sunny light, so it will dry because of sun. While the dried beans will be packaged by using sacks, and then it is distributed to the factory by using train or lorry.

Next, the beans are then baked at a high temperature of 350 degrees in which this process will continue to the next stages. The beans are crushed and separated from their outer shell. In final process, liquid chocolate is produced by pressing inner part.

To begin, the raw material of cacao comes from cacao trees, which is grown in the South American, African and some territorial in Indonesia. After the pods are ripe and red, they can be harvested and the white cocoa is separated in order to be fermented. Following a day of fermentation, they are laid out on the board which spread over to get a sunny light, so it will dry because of sun. While the dried beans will be packaged by using sacks, and then it is distributed to the factory by using train or lorry.

Next, the beans are then baked at a high temperature of 350 degrees in which this process will continue to the next stages. The beans are crushed and separated from their outer shell. In final process, liquid chocolate is produced by pressing inner part.

how_chocolate_is_pro.jpg