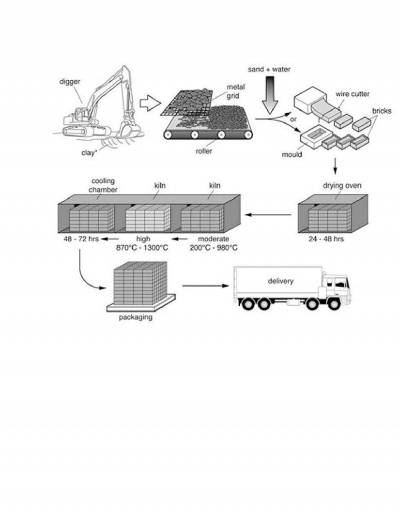

The given chart disrobes the process of making of bricks until transportation to the place of delivery. It consists of three steps, molding bricks from the clay, thermal processing and the delivery of the bricks.

To begin with, in the first step the clay is collected by a digger, and strained by passing it over a metal grid. This process removes big particles from the clay. The clay is kept on a roller and mix with water. This mixed clay is now ready for making bricks. The mixed clay is either pass through the squire box and the wire cutter is using to cut the bricks according to its size, or a mold is using to shape the mixed clay into bricks.

In the second stage, the molded bricks are shifting into the drying room and kept there for 24 to 48 hours. After that it is keeping in the kiln at a moderate temperature of 200 degree to 980 degree first, then high heat of 890 degree to 1300 degree, finally in the cooling the chamber for 48 to 72 hours. At the end of the process, the brick is ready for packing.

The final step consists of packing and delivery. Packed bricks are taken to the place of delivery in big transporting vehicle.

You should spend about 20 minutes on this task.

The diagram illustrates the process that is used to manufacture bricks for the building industry.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

Write at least 150 words.

The Brick Manufacturing Process

To begin with, in the first step the clay is collected by a digger, and strained by passing it over a metal grid. This process removes big particles from the clay. The clay is kept on a roller and mix with water. This mixed clay is now ready for making bricks. The mixed clay is either pass through the squire box and the wire cutter is using to cut the bricks according to its size, or a mold is using to shape the mixed clay into bricks.

In the second stage, the molded bricks are shifting into the drying room and kept there for 24 to 48 hours. After that it is keeping in the kiln at a moderate temperature of 200 degree to 980 degree first, then high heat of 890 degree to 1300 degree, finally in the cooling the chamber for 48 to 72 hours. At the end of the process, the brick is ready for packing.

The final step consists of packing and delivery. Packed bricks are taken to the place of delivery in big transporting vehicle.

You should spend about 20 minutes on this task.

The diagram illustrates the process that is used to manufacture bricks for the building industry.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

Write at least 150 words.

The Brick Manufacturing Process

Doc1page0001__13610.jpg