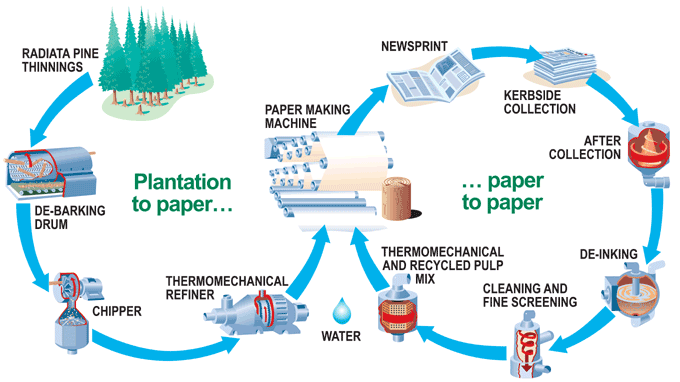

The manufacturing process for making paper that is separated into two types is depicted in the diagram. Overall, it can be seen that papermaking can be made from trees with four-stages process and recycled from paper with six-stages process.

First, pine timber from plantation is taken and made into thinning. Afterwards, the thin piece of pine enters the next process to remove the bark called de-barking in a drum. After the thin piece of pine timber is free from the hard cover, it is made into smaller pieces using a chipper. Once smaller pieces are already created, those pieces move to the following process to thermo mechanical refiner to be formed into smallest pieces of pine timber. The last stage to create a piece of paper is paper making machine that is used to roll those pieces into a sheet of paper.

Second, recycling process from paper to paper is started after paper is used as a newspaper, for instance. After being read, the newspaper is collected in kerbside collection. Next, they are churned and being de-inking to remove ink from the paper. The last two processes before become a clear paper again is cleaning and fine screening to eliminate impurities on it. After cleaning process, next stage is thermo mechanical and recycled pulp mix which is used to mix the pulp. Finally, the pulp product can be rolled to make new paper again.

First, pine timber from plantation is taken and made into thinning. Afterwards, the thin piece of pine enters the next process to remove the bark called de-barking in a drum. After the thin piece of pine timber is free from the hard cover, it is made into smaller pieces using a chipper. Once smaller pieces are already created, those pieces move to the following process to thermo mechanical refiner to be formed into smallest pieces of pine timber. The last stage to create a piece of paper is paper making machine that is used to roll those pieces into a sheet of paper.

Second, recycling process from paper to paper is started after paper is used as a newspaper, for instance. After being read, the newspaper is collected in kerbside collection. Next, they are churned and being de-inking to remove ink from the paper. The last two processes before become a clear paper again is cleaning and fine screening to eliminate impurities on it. After cleaning process, next stage is thermo mechanical and recycled pulp mix which is used to mix the pulp. Finally, the pulp product can be rolled to make new paper again.

Writing_Task_1_Home.png