You should spend about 20 minutes on this task.

The diagram illustrates the process that is used to manufacture bricks for the building industry.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

Write at least 150 words.

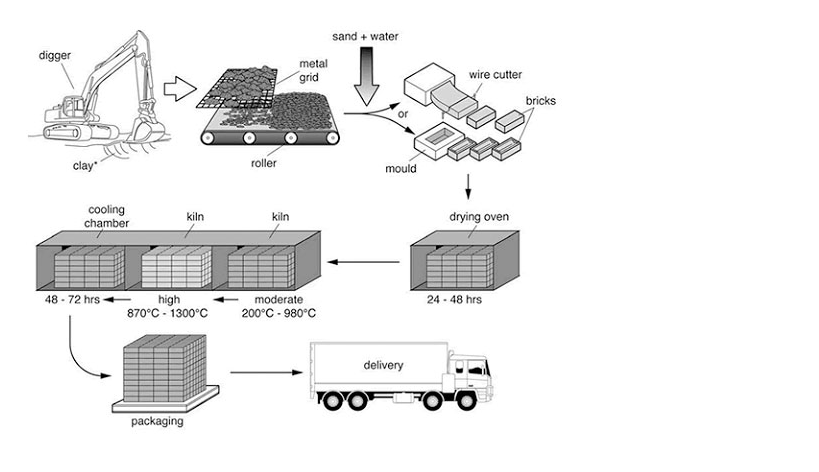

The diagram shows how bricks are produced and supplied to end users. Overall, there are five main stages consisting of digging, shaping, heating, packaging and delivering.

More specifically, bricks are mainly made of clay which is simply mined via diggers. Clay then is filtered through metal grids before rollers bring it to the next step. After added with sand and water, the mixture is divided and shaped into numerous same pieces by cutting or moulding. To be able to use for the building industry, people dry those by an oven from 24 to 48 hours before raising the heat up to 200 - 980 C degree in the moderate mode and 870 - 1300 C degree in the high mode. The last part of the kilning stage is to cool them down in about 48 - 72 hours later. Finally, when products are good qualified, people pack and load them into containers so as to deliver to building constructers.

(155 words)

The diagram illustrates the process that is used to manufacture bricks for the building industry.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

Write at least 150 words.

The diagram shows how bricks are produced and supplied to end users. Overall, there are five main stages consisting of digging, shaping, heating, packaging and delivering.

More specifically, bricks are mainly made of clay which is simply mined via diggers. Clay then is filtered through metal grids before rollers bring it to the next step. After added with sand and water, the mixture is divided and shaped into numerous same pieces by cutting or moulding. To be able to use for the building industry, people dry those by an oven from 24 to 48 hours before raising the heat up to 200 - 980 C degree in the moderate mode and 870 - 1300 C degree in the high mode. The last part of the kilning stage is to cool them down in about 48 - 72 hours later. Finally, when products are good qualified, people pack and load them into containers so as to deliver to building constructers.

(155 words)

Process.png