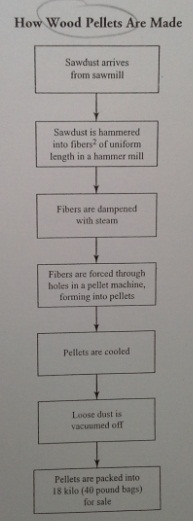

The diagram gives information regarding on the process of making wood pellets for heating buildings. Generally, what stand out from the picture describes that there are eight stages of producing wood pellets from beginning selected material of pellets as the first step to the pellet at the ready to be sold.

With regard to the first three stages, the material of wood pellets which called sawdust arrives from sawmill. Afterward, the sawdust is hammered into fibers of uniform length in a hammer mill to produce fibers, and then the fibers are dampened with steam before it is processed by machine.

Moving to a more detailed analysis from the diagram reveals that in the second five steps, fibers are forced through holes in a pellet machine, forming into pellets before the pellets are cooled to loose dust which is vacuumed off in the next steps. After that, the pellet has been ready to be packed into 18 kilo (140 pound bags) and can be distributed to be sold.

With regard to the first three stages, the material of wood pellets which called sawdust arrives from sawmill. Afterward, the sawdust is hammered into fibers of uniform length in a hammer mill to produce fibers, and then the fibers are dampened with steam before it is processed by machine.

Moving to a more detailed analysis from the diagram reveals that in the second five steps, fibers are forced through holes in a pellet machine, forming into pellets before the pellets are cooled to loose dust which is vacuumed off in the next steps. After that, the pellet has been ready to be packed into 18 kilo (140 pound bags) and can be distributed to be sold.