Thanks a lot for helping me guys

Task 1:

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

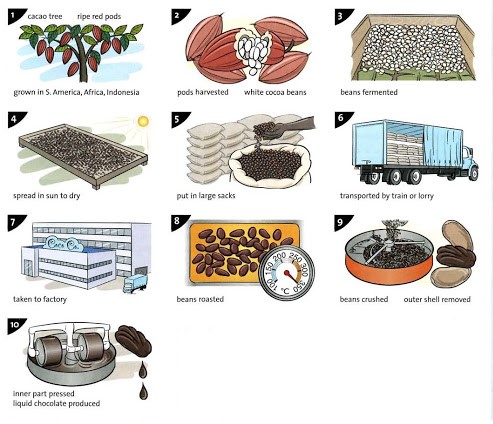

The diagram delineates the step-by-step production of chocolate.

Overall, it is readily apparent that this linear, man-made procedure involves 10 steps, grouped into 4 main stages, starting with the harvesting, followed by raw processing, roasting and finalizing with the formation of the standard chocolate product.

Looking at the first stage, one can see that red pods are riped from the cacao tree, which are grown mainly in South America, Africa, and Indonesia. After being harvested, the pods are cored, taking the white cocoa beans out for further processing. The beans are then fermented in large trays, which subsequently being spread in sun to dry out the moisture. Turning to the next phase, the beans are put in large sacks prior to being transported to the factory by train or lorry.

In the next phases, the beans are roasted at 350 Celcius degrees, before being crushed to remove the outer shell. In the final stages, the inner part is pressed into liquid chocolate, which is the product that customers are commonly familiar with.

Task 1:

The diagram shows how chocolate is produced.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

The diagram delineates the step-by-step production of chocolate.

Overall, it is readily apparent that this linear, man-made procedure involves 10 steps, grouped into 4 main stages, starting with the harvesting, followed by raw processing, roasting and finalizing with the formation of the standard chocolate product.

Looking at the first stage, one can see that red pods are riped from the cacao tree, which are grown mainly in South America, Africa, and Indonesia. After being harvested, the pods are cored, taking the white cocoa beans out for further processing. The beans are then fermented in large trays, which subsequently being spread in sun to dry out the moisture. Turning to the next phase, the beans are put in large sacks prior to being transported to the factory by train or lorry.

In the next phases, the beans are roasted at 350 Celcius degrees, before being crushed to remove the outer shell. In the final stages, the inner part is pressed into liquid chocolate, which is the product that customers are commonly familiar with.

unnamed.jpg