Task 1:

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

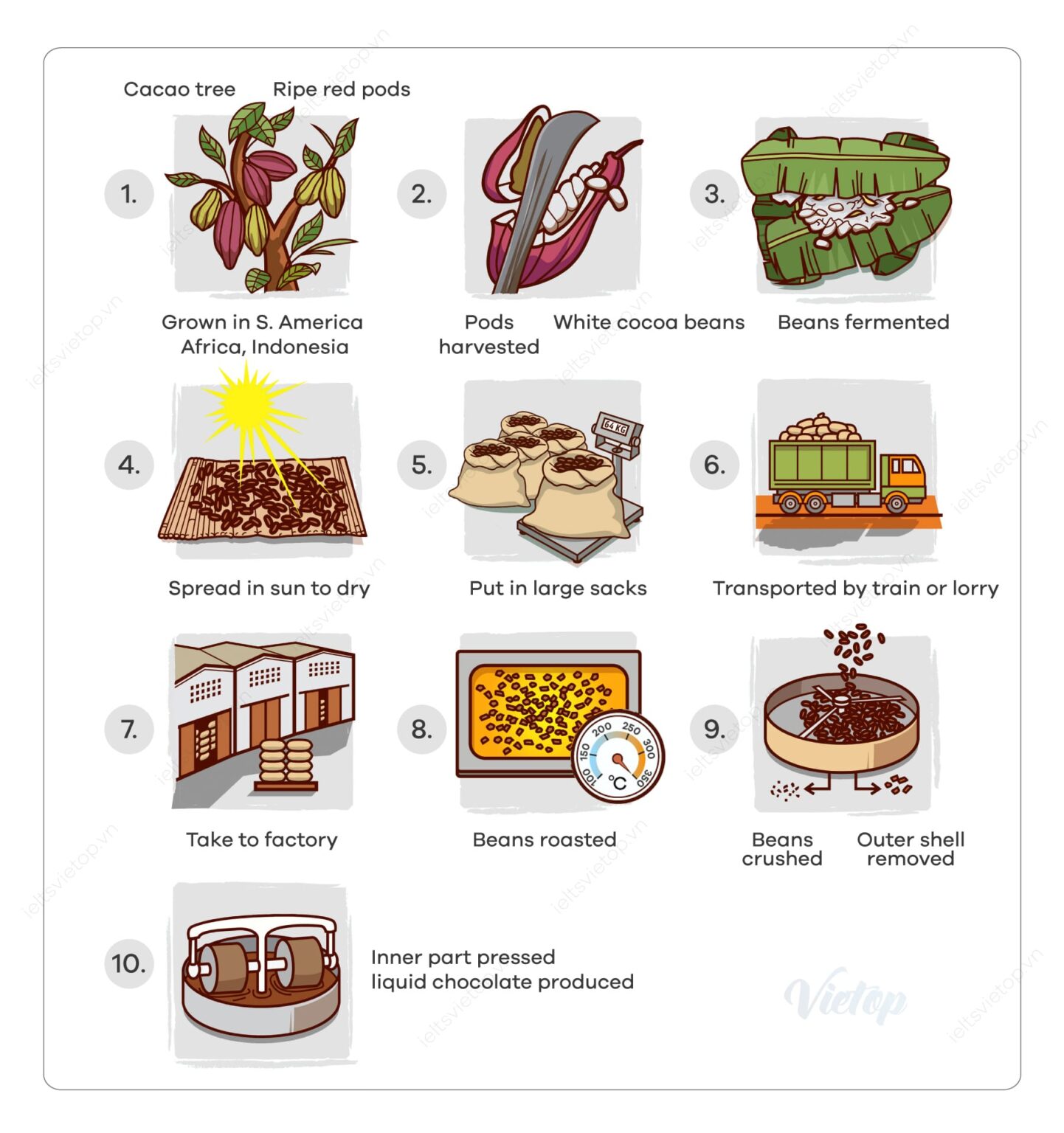

The diagram elaborates on the breakdown of making chocolate.

A course of 10 successive stages has been prominently given, beginning with planting cocoa trees and finishing with producing liquid chocolate.

To commence, the cocoa trees are grown in South America, Africa, and Indonesia with a view to farmers' collecting of red pods to take the raw materials inside them - white cocoa beans. Subsequently, harvested pods are carefully separated into halves, from which the white cocoa beans are extracting. The beans are thereafter continuously fermented between the layers of banana leaves. Following the fermentation, the beans are spread out and prolongedly exposed under the sunlight until they turn brown in order to become dry. In the fifth step, dried beans are loaded in the same-sized large sacks before being moved to the factory by either trains or lorries.

Regarding the chocolate-making procedure in the factory, the beans initially undergo a roasting phase in the ovens at a temperature of 350 Celcius degree, which continually is taken into a flat, cylindrical machine to dispose of the outer shell, and simultaneously crush the roasted beans. Ultimately, the crushed beans are pressed under the high pressure of two rollers for the purpose of forming the liquid chocolate.

The diagram shows how chocolate is produced.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

The diagram elaborates on the breakdown of making chocolate.

A course of 10 successive stages has been prominently given, beginning with planting cocoa trees and finishing with producing liquid chocolate.

To commence, the cocoa trees are grown in South America, Africa, and Indonesia with a view to farmers' collecting of red pods to take the raw materials inside them - white cocoa beans. Subsequently, harvested pods are carefully separated into halves, from which the white cocoa beans are extracting. The beans are thereafter continuously fermented between the layers of banana leaves. Following the fermentation, the beans are spread out and prolongedly exposed under the sunlight until they turn brown in order to become dry. In the fifth step, dried beans are loaded in the same-sized large sacks before being moved to the factory by either trains or lorries.

Regarding the chocolate-making procedure in the factory, the beans initially undergo a roasting phase in the ovens at a temperature of 350 Celcius degree, which continually is taken into a flat, cylindrical machine to dispose of the outer shell, and simultaneously crush the roasted beans. Ultimately, the crushed beans are pressed under the high pressure of two rollers for the purpose of forming the liquid chocolate.

dethiieltswriting.jpg