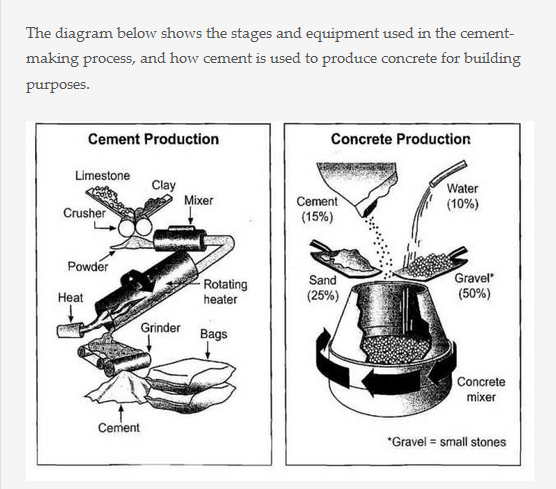

A breakdown of how cement is manufactured and its utilization for building constructions is presented in the graphs. Overall, it is immediately apparent that the cement has to pass through three complicated stages before packaging in the bags. Meanwhile, there are four main material mixed straightforward in order to produce concrete.

Firstly, the raw materials consist of limestone and clay which are mixed together and then it is crushed so as to produce powder. Once the powder has been mixed in the tube mixer, it enters the rotating heater and was heated by heat at the edge of the long tube. Afterwards, it is ground which results in cement. Having packaged in the bag, the cement is ready to sell.

To make concrete, the majority of this composition is a half consisting of gravel and a quarter of sand which are poured into a concrete mixer. Then, 15 percent of cement and 10 percent of water are added to the mixture. Finally, all of the materials are mixed clockwise in the concrete mixer.

Firstly, the raw materials consist of limestone and clay which are mixed together and then it is crushed so as to produce powder. Once the powder has been mixed in the tube mixer, it enters the rotating heater and was heated by heat at the edge of the long tube. Afterwards, it is ground which results in cement. Having packaged in the bag, the cement is ready to sell.

To make concrete, the majority of this composition is a half consisting of gravel and a quarter of sand which are poured into a concrete mixer. Then, 15 percent of cement and 10 percent of water are added to the mixture. Finally, all of the materials are mixed clockwise in the concrete mixer.

Cement_production.pn.png