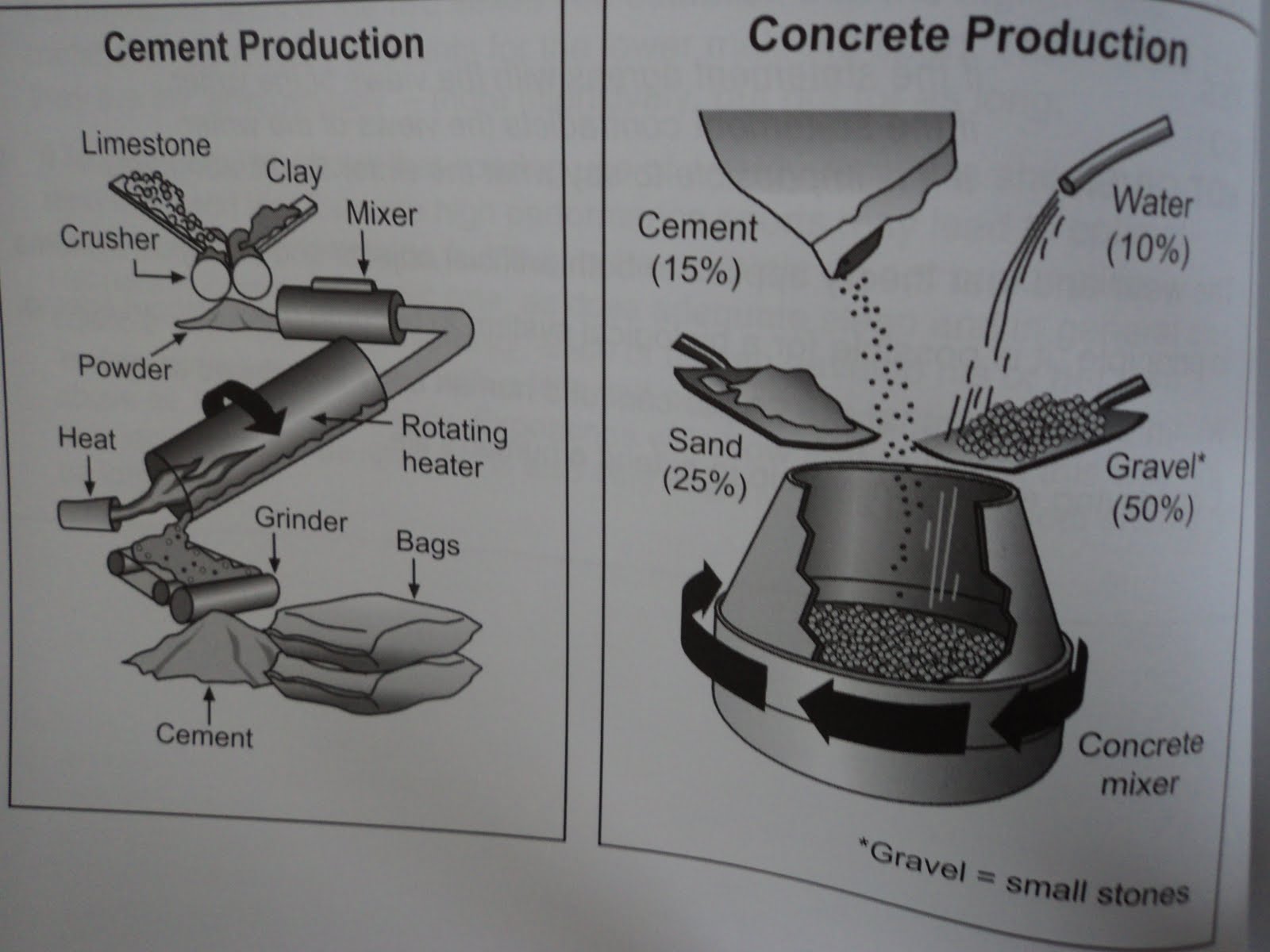

The two diagrams illustrate an overview of the cement production from available devices in purpose to manufacture concrete for construction using.

Overall, the process of making cement involves various stages from the beginning to make an ultimate product. Likewise, there are numbers of prerequisite needed for making a solid concrete.

As per the first diagram, limestone and clay crush in a rolling machine to make a mixed powder. The powder come into a round shape of mixer then pass through the 90 degrees shape of pipe to continue the process. In the third step, mixed powder in the rotating heater burns to melt the powder. The heated powder is grinded in advance prior to be packaged in bags.

Once produced, an initial mixture comprising 15% cement, 10 % water, one-quarter sand and a half gravel is fed onto concrete mixer. Then a concrete mixer running clockwise, it mixes the material to make solid concretes for construction purposes.

Overall, the process of making cement involves various stages from the beginning to make an ultimate product. Likewise, there are numbers of prerequisite needed for making a solid concrete.

As per the first diagram, limestone and clay crush in a rolling machine to make a mixed powder. The powder come into a round shape of mixer then pass through the 90 degrees shape of pipe to continue the process. In the third step, mixed powder in the rotating heater burns to melt the powder. The heated powder is grinded in advance prior to be packaged in bags.

Once produced, an initial mixture comprising 15% cement, 10 % water, one-quarter sand and a half gravel is fed onto concrete mixer. Then a concrete mixer running clockwise, it mixes the material to make solid concretes for construction purposes.

diagram_making_cemen.jpg