Sweet carbohydrates

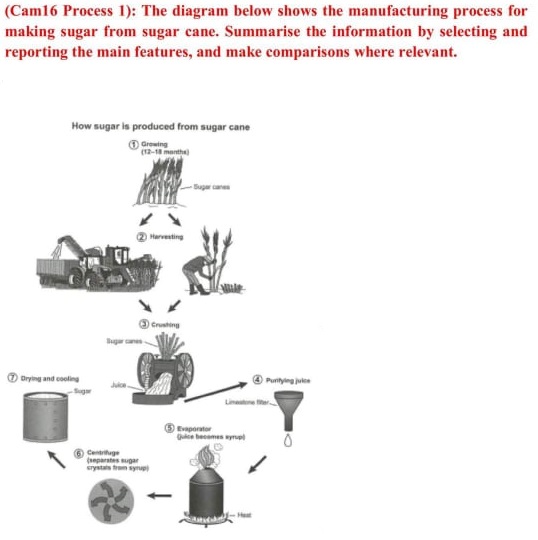

The graph illustrates the process through which sugar is produced from sugar cane.

Overall, after being cultivated for one year to one and a half years, sugar canes are harvested by hand or machine, removed all the leaves to become the raw material which is the main input of a five-step procedure of extracting and purifying sugar.

To obtain the juice rich in sugar, a crushing machine is used to drain the liquid from the fibre structure of sugar canes, leaving the dry solid waste. The juice is then cleaned by a limestone filter which removes the remaining solid pieces and other impurities. After these two procedures, a purified sugar juice is produced.

The purified sugar liquid is then evaporated by heat to eliminate a partial amount of water. The major purpose of this step is to obtain a syrup containing sugar at a smaller concentration, which is crucial for sugar crystallization in the following steps. To yield the partition of sugar crystals from the semi-liquid part, a centrifuge is used, separates solid and liquid parts due to the centrifugal force at high spinning speed and the density difference. In the last step, sugar crystals are placed in a container to be cooled down and dry and become the finished product of the whole manufacturing process.

215398478_1428895579.jpg