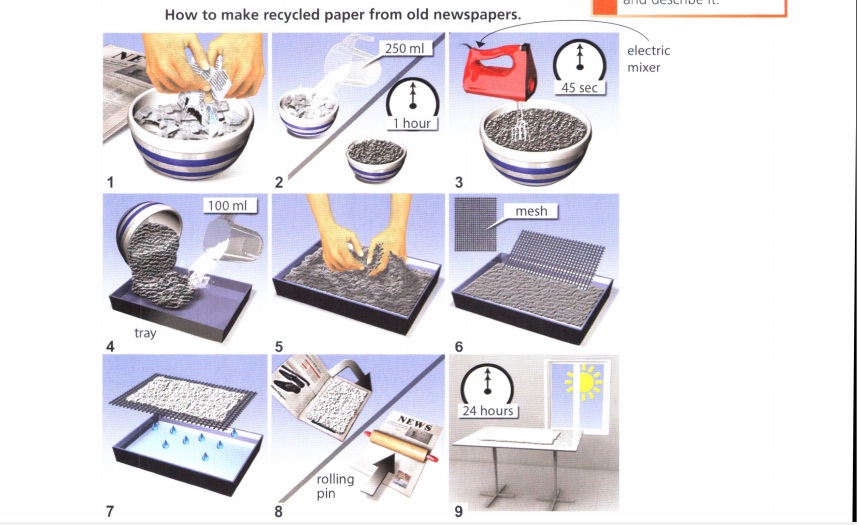

The recycling process of old newspapers into paper is described in the given diagram. Generally, it can be noticed that nine steps should be completed to turn a paper waste into a new white recycled paper.

The process is started with tearing the newspaper up into pieces. Subsequently, the pieces placed in a bowl is poured 250 ml of water and left for an hour in order to soften it like a porridge. The porridge-like paper, then, is stirred by using an electric mixer for 45 seconds. Afterward, the well-mixed paper is spread in a tray with adding 100 ml of liquefied flour to make a paper dough. Prior to covering with mesh in the top of the paper dough, it should be solidified manually by hand. The mesh function is filtering the porridge from excess water and making it compact. Having been compacted, the porridge is molded into paper by rolling pin. Finally, the paper is dried with sufficient heat from the sun for a day.

The process is started with tearing the newspaper up into pieces. Subsequently, the pieces placed in a bowl is poured 250 ml of water and left for an hour in order to soften it like a porridge. The porridge-like paper, then, is stirred by using an electric mixer for 45 seconds. Afterward, the well-mixed paper is spread in a tray with adding 100 ml of liquefied flour to make a paper dough. Prior to covering with mesh in the top of the paper dough, it should be solidified manually by hand. The mesh function is filtering the porridge from excess water and making it compact. Having been compacted, the porridge is molded into paper by rolling pin. Finally, the paper is dried with sufficient heat from the sun for a day.

Diagram1Paper_maki.jpg