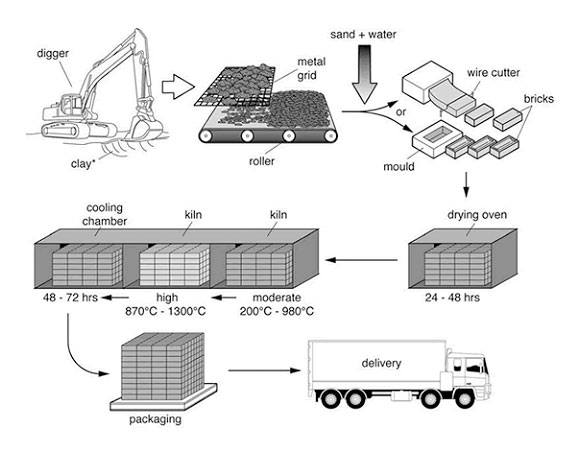

Diagram illustrates the process that is used to manufacture bricks for the building industry.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

The diagram presents the process that is used to produce bricks to construct a building factory. Overall, it can be seen that, the method of production are complex through six stages before bricks are sold.

First, the clay are dug by digger, following this the clay is taken and afterwards, spread out on the metal grid. Then it is rolled on roller. Next, the clay are mixed with sand and water. Next, it is inputed to mould or wide cutter. Then bricks are inputed on drying oven for 24 or 48 hours. Following this, the brick inputted to kiln moderate with temperature 200 degree celcius-980 degree celcius and the briks are continued to high kil with temperature 870 degree celcius-1300 degree celcius. Before being packed , the bricks are inputed to colling chamber fo 48-72 hours. After the bricks are packed, the brick are ready to be stored by car.

Summarize the information by selecting and reporting the main features and make comparisons where relevant.

The diagram presents the process that is used to produce bricks to construct a building factory. Overall, it can be seen that, the method of production are complex through six stages before bricks are sold.

First, the clay are dug by digger, following this the clay is taken and afterwards, spread out on the metal grid. Then it is rolled on roller. Next, the clay are mixed with sand and water. Next, it is inputed to mould or wide cutter. Then bricks are inputed on drying oven for 24 or 48 hours. Following this, the brick inputted to kiln moderate with temperature 200 degree celcius-980 degree celcius and the briks are continued to high kil with temperature 870 degree celcius-1300 degree celcius. Before being packed , the bricks are inputed to colling chamber fo 48-72 hours. After the bricks are packed, the brick are ready to be stored by car.

tgl_8.jpg