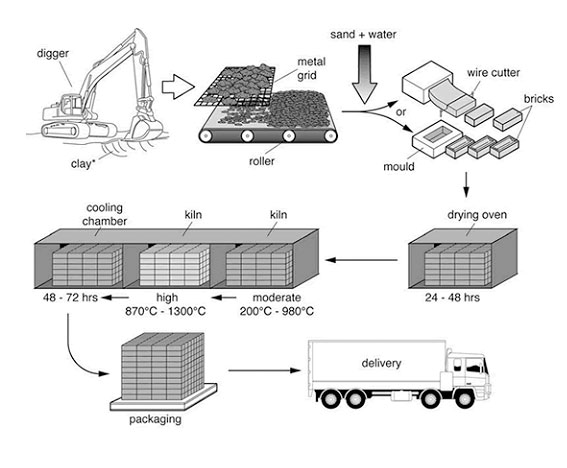

The diagram illustrates the process that is used to manufacture bricks for the building industry.

The illustration describes the process in which bricks are made for constructing purposes. As can be seen from the diagram, there are seven steps in total, beginning with collecting clay and finishing with delivering the products.

In the first place, clay is dug by a digger, then cut into smaller pieces by a metal grid and moved on a roller. The initial product is mixed with sand and water after that. In the next stage, the combination is shaped into brick form either by a wire cutter or a mould.

The fourth step is hardening the original bricks using a drying oven during a period of 24 to 48 hours. Next, these products experience extreme heat ranging between 200 Celsius degrees and 1300 Celsius degrees in the kiln before penetrating the cooling process in the chamber for 2 to 3 days. After that, packaging takes place and the well - done bricks are eventually transferred on a truck.

Process of making bricks

The illustration describes the process in which bricks are made for constructing purposes. As can be seen from the diagram, there are seven steps in total, beginning with collecting clay and finishing with delivering the products.

In the first place, clay is dug by a digger, then cut into smaller pieces by a metal grid and moved on a roller. The initial product is mixed with sand and water after that. In the next stage, the combination is shaped into brick form either by a wire cutter or a mould.

The fourth step is hardening the original bricks using a drying oven during a period of 24 to 48 hours. Next, these products experience extreme heat ranging between 200 Celsius degrees and 1300 Celsius degrees in the kiln before penetrating the cooling process in the chamber for 2 to 3 days. After that, packaging takes place and the well - done bricks are eventually transferred on a truck.

xieltsprocessbrick.jpg