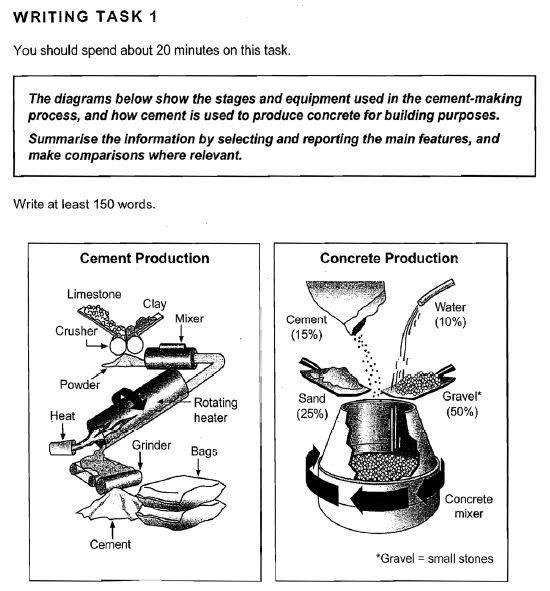

The diagrams show the process of making cement which usually used to concrete production. Overall, cement process is more complicated than making concrete.

In the beginning of making cement, we need raw materials (limestone and clay) and it is crunched into powder. After that, it is passed through mixer and rotating heater until becoming lava texture. Next, it is grinded into powder again and packed it.

To make concrete. First, we make an amalgam of materials (15 percent of cement which produced from first diagram, 10 percent of water, 25 percent of sand and 50 percent of gravel which called small stones). After that, we pour into big rotating machine which is called concrete mixer to mix the ingredients of concrete. Finally, it is mixed until smooth and concrete can be used for making a wall.

In the beginning of making cement, we need raw materials (limestone and clay) and it is crunched into powder. After that, it is passed through mixer and rotating heater until becoming lava texture. Next, it is grinded into powder again and packed it.

To make concrete. First, we make an amalgam of materials (15 percent of cement which produced from first diagram, 10 percent of water, 25 percent of sand and 50 percent of gravel which called small stones). After that, we pour into big rotating machine which is called concrete mixer to mix the ingredients of concrete. Finally, it is mixed until smooth and concrete can be used for making a wall.

akhir_cuy.jpg