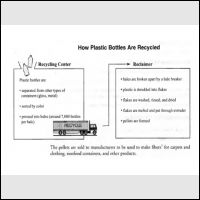

This diagram illustrates the steps of recycling bottles which are formed from plastic for new innovation. Overall, pellet is formed by plastic.

First of all, plastic bottles have some requirements; separated from other kinds of containers such as glass and metal. Then these bottles are sorted by color. Next, those are pressed into some bales (approximately seven thousand bottles per bale) as its measurement is suitable for processing bottles.

Furthermore, all of these bottles which completed whole requirements are brought by big truck to reclaimer. This reclaimer will process plastic jugs to be pellet, it needs some steps. First, bales are broken apart by a bale breaker. Ten plastics which are got from bale breaker are shredded into flakes. Afterwards, those flakes should be washed, rinsed and dried. Then, they are melted and put through ext-ruder. Finally, pellets are formed.

Seller sells these pellets to manufactures used to make some fibers to some daily basis such as carpets and clothing, and nonfood containers and those are used to other products as well.

First of all, plastic bottles have some requirements; separated from other kinds of containers such as glass and metal. Then these bottles are sorted by color. Next, those are pressed into some bales (approximately seven thousand bottles per bale) as its measurement is suitable for processing bottles.

Furthermore, all of these bottles which completed whole requirements are brought by big truck to reclaimer. This reclaimer will process plastic jugs to be pellet, it needs some steps. First, bales are broken apart by a bale breaker. Ten plastics which are got from bale breaker are shredded into flakes. Afterwards, those flakes should be washed, rinsed and dried. Then, they are melted and put through ext-ruder. Finally, pellets are formed.

Seller sells these pellets to manufactures used to make some fibers to some daily basis such as carpets and clothing, and nonfood containers and those are used to other products as well.

251573_1.jpg