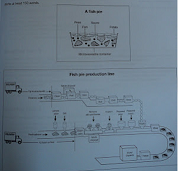

The diagrams below give information about the manufacture of frozen fish pies.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

The two diagrams provide a breakdown of manufacturing frozen fish pies. Overall, what stands out from the diagrams reveals that microwaveable container contains four mixed ingredients. In addition, there are two different ways of fish pie production line before mixing in potato.

According to the first diagram, producing a fish pie needs four important materials. Microwaveable container contains these materials into different place. While potato is placed on the top, both fish and peas are more likely to have different place that is sometimes in the middle and in the bottom. Likewise, sauce tends to fill all empty spaces.

A more detailed look at the data describes that fish pie production line can be done in two ways. First of all, raw potatoes are delivered by car around a month. Afterwards, these potatoes are cleaned then pealing in waste disposal. The next step is that after potatoes have been peeled, these potatoes are sliced, and then boiling into pan. Adding chill and storing them are done before mixing into potato. The second way is after delivering for 12 hours or less, fresh salmon is mixed by lemon juice and salt with aim of preventing bad smell. Steaming into the oven is the next step. After that, removing skin and bones is done by employees then throwing them into waste disposal. Inspecting and prepared peas and sauces are done before mixing with potato. Then wrapping, and packaging in freeze into store/dispatch.

Summarise the information by selecting and reporting the main features, and make comparisons where relevant.

The two diagrams provide a breakdown of manufacturing frozen fish pies. Overall, what stands out from the diagrams reveals that microwaveable container contains four mixed ingredients. In addition, there are two different ways of fish pie production line before mixing in potato.

According to the first diagram, producing a fish pie needs four important materials. Microwaveable container contains these materials into different place. While potato is placed on the top, both fish and peas are more likely to have different place that is sometimes in the middle and in the bottom. Likewise, sauce tends to fill all empty spaces.

A more detailed look at the data describes that fish pie production line can be done in two ways. First of all, raw potatoes are delivered by car around a month. Afterwards, these potatoes are cleaned then pealing in waste disposal. The next step is that after potatoes have been peeled, these potatoes are sliced, and then boiling into pan. Adding chill and storing them are done before mixing into potato. The second way is after delivering for 12 hours or less, fresh salmon is mixed by lemon juice and salt with aim of preventing bad smell. Steaming into the oven is the next step. After that, removing skin and bones is done by employees then throwing them into waste disposal. Inspecting and prepared peas and sauces are done before mixing with potato. Then wrapping, and packaging in freeze into store/dispatch.

task1_process.PNG