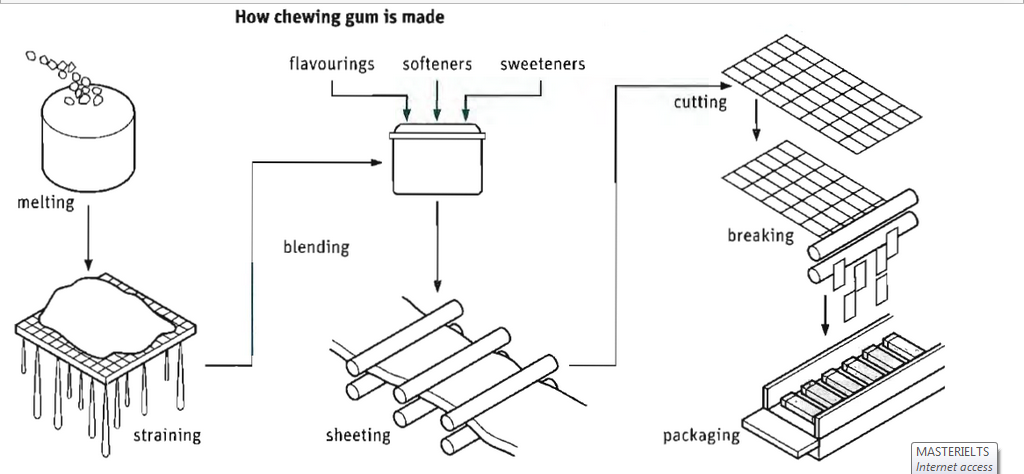

The way in which chewing gum is made in terms of manufacturing process is presented in the diagram. Overall, there are seven stages in the process, beginning with melting the spruce gum and culminating in packaging process.

To begin with, the spruce gum used to make chewing gum is boiled in high temperature water until be melted. This spruce gum is then put into certain container used to strain it so that it can be separated from its liquid.

Following this, some ingredients such as flavorings, softeners, and sweeteners are added to that spruce, and this mixture is blended one another. The roller machine used to flatten passed the mixture. Furthermore, this chewing gum is cut into some small parts. In the subsequent stage, it goes through a breaking and packaging process. The flatten mixture cut are broken off into some small pieces, afterwards these wrapped and packed using packaging machine. Finally, these chewing gums are ready to be distributed.

To begin with, the spruce gum used to make chewing gum is boiled in high temperature water until be melted. This spruce gum is then put into certain container used to strain it so that it can be separated from its liquid.

Following this, some ingredients such as flavorings, softeners, and sweeteners are added to that spruce, and this mixture is blended one another. The roller machine used to flatten passed the mixture. Furthermore, this chewing gum is cut into some small parts. In the subsequent stage, it goes through a breaking and packaging process. The flatten mixture cut are broken off into some small pieces, afterwards these wrapped and packed using packaging machine. Finally, these chewing gums are ready to be distributed.

process_diagram.png