Hi guys,

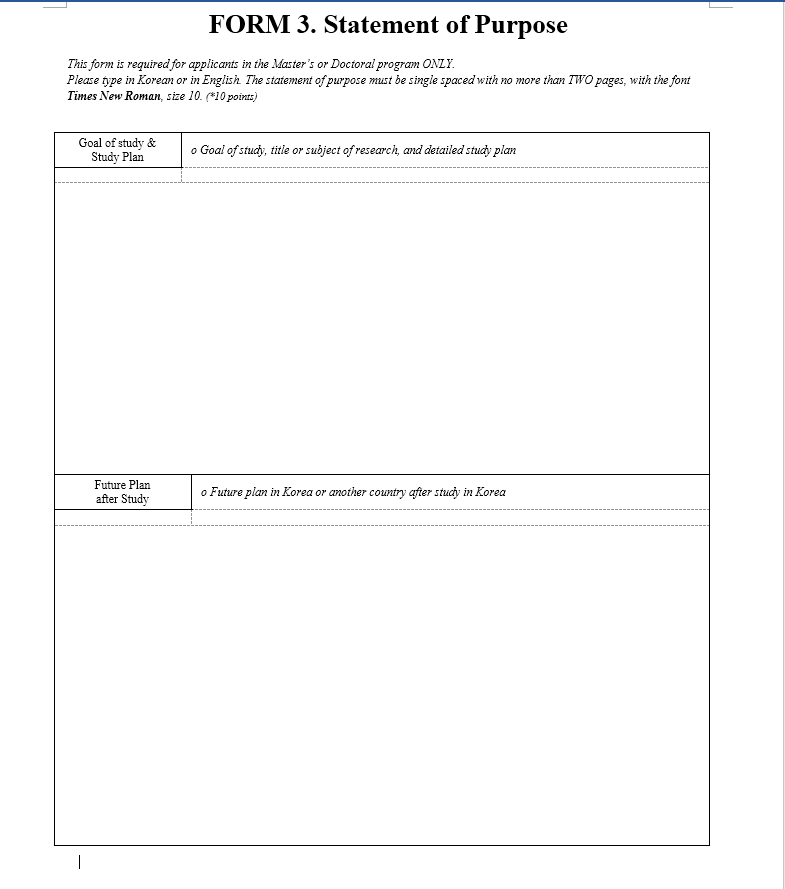

This is my study plan for KGSP scholarship, please help me make it more compelling to the reviewer. Thanks in advanced.

@Holt Please review it, your advice alone means a lot. Thanks a million for your non-stop effort.

The decision of moving towards pursuing my master's degree soon after getting my bachelor's one is accompanied with a clear goal. With the strong knowledge in the field of Polymer Engineering that I have earned in my bachelor's program still fresh in my mind, and the knowledge that I would gain during my higher studies at the department of Energy and Chemical Engineering at XYZ institute, the path to realize my master's research opens greater possibilities. Hence, by learning more about inorganic and organic material chemistry through the energy and chemical engineering program, I hope my study could bring a greater benefit not only for the material industry but for the energy sector as well.

During my period as a master's student at XYZ, I am interested to do a research on exploring newer possibilities with 3D printing, particularly on the FDM technology. 3D printing is the pioneer of manufacturing industry in the present world and provides excellent results in making prototypes and custom shaped complex parts in less time and with reduced cost. According to UK Trade & Investment, 3D printing is one of the major South Korea's growth engines for the future. As 3D printing grows in popularity and with projects being scaled in every industry, it will also fuel the global consumption of polymeric products, and consequently polymeric waste materials as well. Although the plastic recycling and reprocessing rates are considerably high, physical properties and economical values of the recycled plastics are significantly low, limiting the reuse of recycled plastics in many industrial applications. Nevertheless, by integrating nanotechnology into recycling technology, we can not only enhance the quality of the recycled end products but can also make plastic recycling more commercially attractive.

3D printing has remained a focus of research since the last two decades, with studies limited to not only the material engineering sector but also in the area of chemical engineering and biotechnology. However, there remains a lot of room for further research as not many materials can be used when it comes to 3D printing due to the difficulties associated with the parameters regarding successful molding. Therefore, owing to these concerns, I am interested in working on making a nanocomposite filament for Fused Deposition Modeling from recycled commodity polymers like HDPE and PP, while also determining their processing conditions. The aim of this research is to produce economically appealing high strength filaments for 3D printing while also reducing plastic pollution.

While HDPE and PP are the most common commodity polymers, not much work has been done on them as feed for 3D printing. As the annual waste generated by these polymers is quite high, recycling them for using as 3D printing filament will not only cut down the burden on solid waste management, but will also make 3D printing cheaper for making things such as living hinges etc. that are best made from such polymers. Moreover, depending on the application, different nano filler reinforcement materials can be integrated in this study. These may range from the seemingly promising graphene nanotubes, to produce ultra-high strength filaments of excellent electrical properties that could be used for manufacturing high performance batteries, supercapacitors and aircraft parts, to inexpensive nanoclays that can be used to produce filaments of suitably high strength and toughness for its application in automotive industries. As various methods to incorporate these nano fillers in polymer matrix are already present, the research may emphasis on producing filaments from them through melt extrusion, and then studying their physical and thermal properties including tensile strength, Young's modulus and MFI for effective 3D printing.

The outcomes from this practically focused research can benefit several different industries, including aerospace industry, automotive industry, as well as electronic industry, and at the same time will reduce the impact of plastic waste on the environment.

At XYZ, innovation and research focused on practical use to build a better society is always appreciated. Furthermore, the Department of Energy and Chemical Engineering offers a radical curriculum with key courses such as Advance Organic Chemistry, Advanced Energy Materials and Advanced Rheology, that can provide me with immediate knowledge necessary for my research. There is also the Lab dedicated to Polymer Processing Research in the department that I am very interested to join. One of the main focuses of the Polymer Processing Researching Lab is the recycling of wasted polymers, which I hope will help me greatly with my research. This makes XYZ an ideal ground for me to carry on my further studies.

I sought for an institution that could offer not only great teaching, but could also provide the individual with versatility, with the capacity to add to society, and with the constant desire to grow and seek self-improvement and with the way to go after it. I believe that XYZ will help me in accomplishing this goal.

This is my study plan for KGSP scholarship, please help me make it more compelling to the reviewer. Thanks in advanced.

@Holt Please review it, your advice alone means a lot. Thanks a million for your non-stop effort.

the path to realize my master's research

The decision of moving towards pursuing my master's degree soon after getting my bachelor's one is accompanied with a clear goal. With the strong knowledge in the field of Polymer Engineering that I have earned in my bachelor's program still fresh in my mind, and the knowledge that I would gain during my higher studies at the department of Energy and Chemical Engineering at XYZ institute, the path to realize my master's research opens greater possibilities. Hence, by learning more about inorganic and organic material chemistry through the energy and chemical engineering program, I hope my study could bring a greater benefit not only for the material industry but for the energy sector as well.

During my period as a master's student at XYZ, I am interested to do a research on exploring newer possibilities with 3D printing, particularly on the FDM technology. 3D printing is the pioneer of manufacturing industry in the present world and provides excellent results in making prototypes and custom shaped complex parts in less time and with reduced cost. According to UK Trade & Investment, 3D printing is one of the major South Korea's growth engines for the future. As 3D printing grows in popularity and with projects being scaled in every industry, it will also fuel the global consumption of polymeric products, and consequently polymeric waste materials as well. Although the plastic recycling and reprocessing rates are considerably high, physical properties and economical values of the recycled plastics are significantly low, limiting the reuse of recycled plastics in many industrial applications. Nevertheless, by integrating nanotechnology into recycling technology, we can not only enhance the quality of the recycled end products but can also make plastic recycling more commercially attractive.

3D printing has remained a focus of research since the last two decades, with studies limited to not only the material engineering sector but also in the area of chemical engineering and biotechnology. However, there remains a lot of room for further research as not many materials can be used when it comes to 3D printing due to the difficulties associated with the parameters regarding successful molding. Therefore, owing to these concerns, I am interested in working on making a nanocomposite filament for Fused Deposition Modeling from recycled commodity polymers like HDPE and PP, while also determining their processing conditions. The aim of this research is to produce economically appealing high strength filaments for 3D printing while also reducing plastic pollution.

While HDPE and PP are the most common commodity polymers, not much work has been done on them as feed for 3D printing. As the annual waste generated by these polymers is quite high, recycling them for using as 3D printing filament will not only cut down the burden on solid waste management, but will also make 3D printing cheaper for making things such as living hinges etc. that are best made from such polymers. Moreover, depending on the application, different nano filler reinforcement materials can be integrated in this study. These may range from the seemingly promising graphene nanotubes, to produce ultra-high strength filaments of excellent electrical properties that could be used for manufacturing high performance batteries, supercapacitors and aircraft parts, to inexpensive nanoclays that can be used to produce filaments of suitably high strength and toughness for its application in automotive industries. As various methods to incorporate these nano fillers in polymer matrix are already present, the research may emphasis on producing filaments from them through melt extrusion, and then studying their physical and thermal properties including tensile strength, Young's modulus and MFI for effective 3D printing.

The outcomes from this practically focused research can benefit several different industries, including aerospace industry, automotive industry, as well as electronic industry, and at the same time will reduce the impact of plastic waste on the environment.

At XYZ, innovation and research focused on practical use to build a better society is always appreciated. Furthermore, the Department of Energy and Chemical Engineering offers a radical curriculum with key courses such as Advance Organic Chemistry, Advanced Energy Materials and Advanced Rheology, that can provide me with immediate knowledge necessary for my research. There is also the Lab dedicated to Polymer Processing Research in the department that I am very interested to join. One of the main focuses of the Polymer Processing Researching Lab is the recycling of wasted polymers, which I hope will help me greatly with my research. This makes XYZ an ideal ground for me to carry on my further studies.

I sought for an institution that could offer not only great teaching, but could also provide the individual with versatility, with the capacity to add to society, and with the constant desire to grow and seek self-improvement and with the way to go after it. I believe that XYZ will help me in accomplishing this goal.