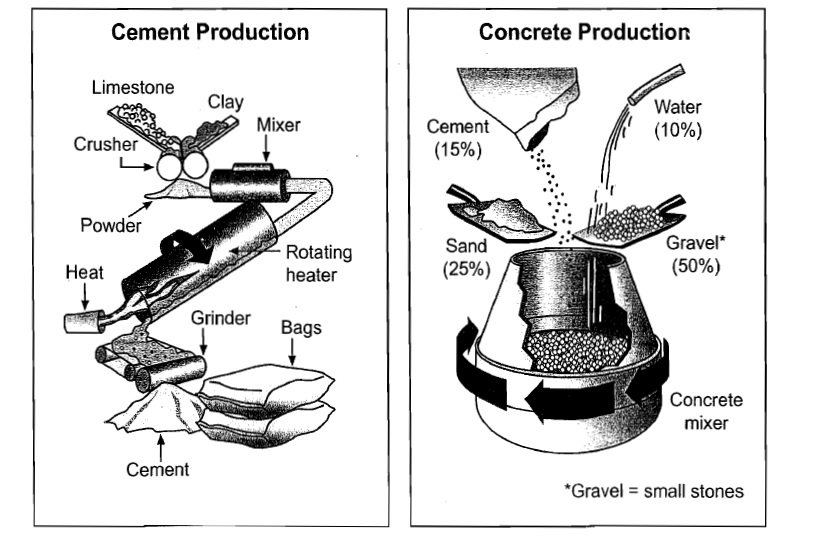

The given diagrams provide an overview of the production of cement from available devices as well as how cement is used to manufacture concrete for construction purpose.

Overall, the cement production involves various stages from the beginning to ultimate product. Likewise, there are a number of prerequisites needed in the making of concrete.

With regard to the first diagram, limestone and clay are initially crushed by a crusher to form powder. Subsequently powder is then mixed prior to being carried into a rotating heater. In this step, a fire is required with the aim of guaranteeing heating. After that, the materials are then grounded to be converted into cement prior to packaging in bags.

Once produced, cement is one of the five inputs of producing concrete, accounting for 15% of the total mixture. Gravel, simultaneously, takes up the highest proportion with 50%. Besides, water and sand constitute the remaining 10% and 25%, respectively. Then a concrete mixer running clockwise is responsible for manufacturing final concrete from five aforementioned elements.

Overall, the cement production involves various stages from the beginning to ultimate product. Likewise, there are a number of prerequisites needed in the making of concrete.

With regard to the first diagram, limestone and clay are initially crushed by a crusher to form powder. Subsequently powder is then mixed prior to being carried into a rotating heater. In this step, a fire is required with the aim of guaranteeing heating. After that, the materials are then grounded to be converted into cement prior to packaging in bags.

Once produced, cement is one of the five inputs of producing concrete, accounting for 15% of the total mixture. Gravel, simultaneously, takes up the highest proportion with 50%. Besides, water and sand constitute the remaining 10% and 25%, respectively. Then a concrete mixer running clockwise is responsible for manufacturing final concrete from five aforementioned elements.

197216_1_o.jpg