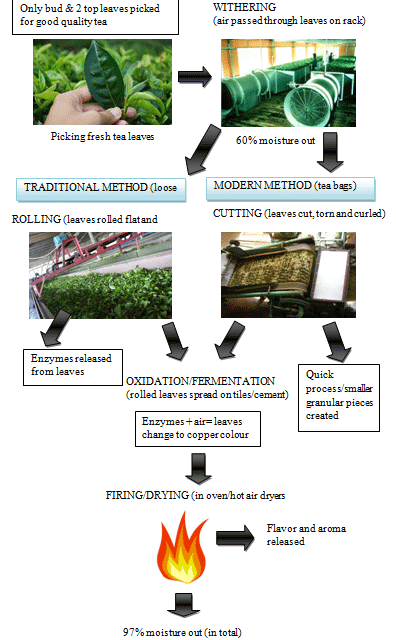

The diagram illustrates the manufacturing processes for producing good black tea. Overall, there are five steps for creating black tea. In any case, even though there are two different ways -traditional and modern methods, they have similar steps in initial and eventual process.

First of all, when collecting tea, the tea farmer picks only bud and 2 top leaves for resulting good quality of tea. Then, the tea continues to withering where leaves are spread out on the rack and air is passed through whole those leaves which can remove about 60% moisture. Following this, the leaves are ready for rolling and cutting, factories use traditional method by rolling flat and broken them which release a wide range of enzymes from leaves, and modern way by cutting leaves, tearing and curling them which created granular pieces. The next step is oxidation, where enzymes are mixed by water can change leave's colour to cooper. Finally, these leaves are fried or dried in hot air dryers where release nice smell, and the leaves only consist of 3% moisture.

First of all, when collecting tea, the tea farmer picks only bud and 2 top leaves for resulting good quality of tea. Then, the tea continues to withering where leaves are spread out on the rack and air is passed through whole those leaves which can remove about 60% moisture. Following this, the leaves are ready for rolling and cutting, factories use traditional method by rolling flat and broken them which release a wide range of enzymes from leaves, and modern way by cutting leaves, tearing and curling them which created granular pieces. The next step is oxidation, where enzymes are mixed by water can change leave's colour to cooper. Finally, these leaves are fried or dried in hot air dryers where release nice smell, and the leaves only consist of 3% moisture.

black_tea.PNG