the processing of beer

Question: The diagram below shows the various stages involved in the production of beer

Answer:

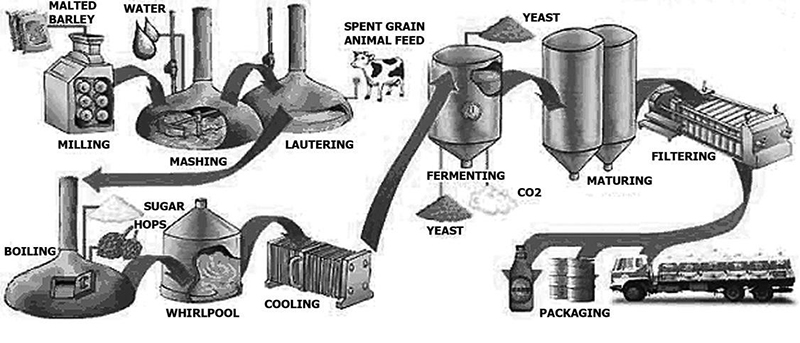

The flow chart illustrates the processing of beer from raw material to a final product.

Overall, there are ten stages in the process, beginning with malted barley milling and ending with product packaging and delivery.

The first stage of the beer production is that malted barley Is milled in a miller, then the barley powder is mixed with water and is mashed in a mashing machine. Subsequently, the mixture is lautered in a special tank and the spent grain is separated from the mixture after this stage. In boiling stage, the liquid after lautering is boiled and then transferred to a whirlpool. In the whirlpool, sugar and hops are added to mix with the boiled liquid. After that, the mixture is cooled by a heat exchanger.

At the fermentation stage, the cooled liquid is fermented with yeast in a fermentation tank. Carbon dioxide and remaining yeast are removed from the tank after fermentation process and the fermented liquid is matured in some tanks for a certain period before it is filtered by a filter. Finally, the filtered liquid is packaged and delivered to consuming markets.

[185 words]

Process1.jpg